Exploring 12 Common Sensor Types & Their Impact on Performance, Safety, & Convenience From kitchen appliances to vehicles, electronic sensors have long been essential components inside the devices we enjoy as a society. Sensors are used to detect...

Exploring 12 Common Sensor Types & Their Impact on Performance, Safety, & Convenience From kitchen appliances to vehicles, electronic sensors have long been essential components inside the devices we enjoy as a society. Sensors are used to detect...

Why CAI is Your Wire Harness Cost Savings Solution In the increasingly competitive world of modern manufacturing, wire harnesses are essential components across a broad range of industries, from automotive and aerospace to industrial machinery and consumer...

Intricate Wire Harnesses Require Custom Solutions From Trusted Experts Used in countless electrical applications, wire harnesses come in all shapes, sizes, and complexities. While a “simple” wire harness organizes a handful of wires into a bundle for basic...

Ensuring Optimal Safety in Wire Harness Design The ability to control and utilize electricity — for everything from lighting homes to powering cars — is easily one of history’s greatest achievements, leading to many of our modern conveniences. However, there...

Extreme Conditions Call for Extra Consideration in Wire Harness Manufacturing Wire harnesses must be carefully crafted in order to effectively supply power and data to the machines and devices we use in our homes and businesses every day. The same is true for...

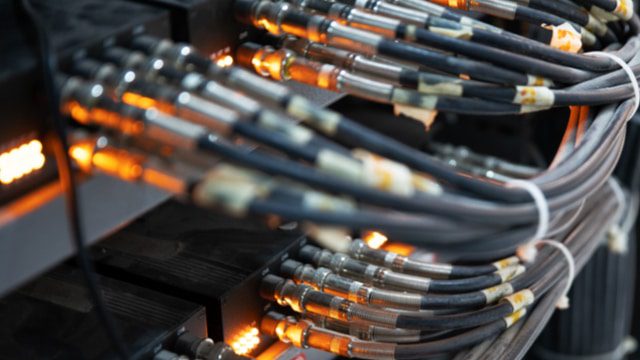

We’ve all experienced it — the frustration of a dropped call, spotty WIFI or that radio station that attempts to power through static. Telecommunications, or “communication over a distance by cable, telegraph or broadcasting,” has never been more important than the present for distance communications. As consumers all over the world are learning how to work from home, shop online and effectively utilize telehealth options, the correct wiring is — quite literally — what keeps us running smoothly. Make sure your Your telecommunications is safeguarded with CAI Manufacturing.

CAI produces personalized, high-quality solutions for the telecommunications market, and prides itself on products that exceed the expectations and individualized attention of every client it serves. We also offer IP67 cable connections and overmolds to add an additional layer of protection for your wires. These overmolds prevent damage from dust and water, extending the lifespan of your equipment. Overmolding allows CAI to use injection molding, combining wire and connectors into a single piece that can be customized to specification.

Since the world depends on communication solutions for nearly every aspect of life, it’s important to remember that protecting wires is one of the most important steps of ensuring that there are as few disruptions as possible. CAI uses potting — the process of fully filling an electrical component to aid in the resistance of shock and vibration, and the prevention of water, moisture, and corrosion — to protect the product. This process has been used to equip plugs and connectors, cables, and wire harnesses and more with additional environmental protection.

Since 1986, CAI has delivered custom, high-quality components and wire harness manufacturing to customers across the globe. Offering a personalized approach to every project, CAI partners with customers to create innovative products that exceed industry standards.

Whether we’re creating niche product prototypes or helping a customer turn their idea into a full production run, CAI’s turnkey manufacturing approach delivers a complete product from design to delivery.

Our expertise allows us to produce cost-effective wire harnessing solutions in most any equipment project and ensure your your telecommunications is safeguarded with CAI Manufacturing. Our expertise allows us to understand the idiosyncrasies of your detailed plans and why following your process is so important. Our personalized, customer-centric process will make sure that your project’s every need is met.

For more information on why our wire harnessing process is the best fit for your project, visit the wire harnessing page on our website or reach out to our team to start work on your custom project.