DESIGN TO DELIVERY

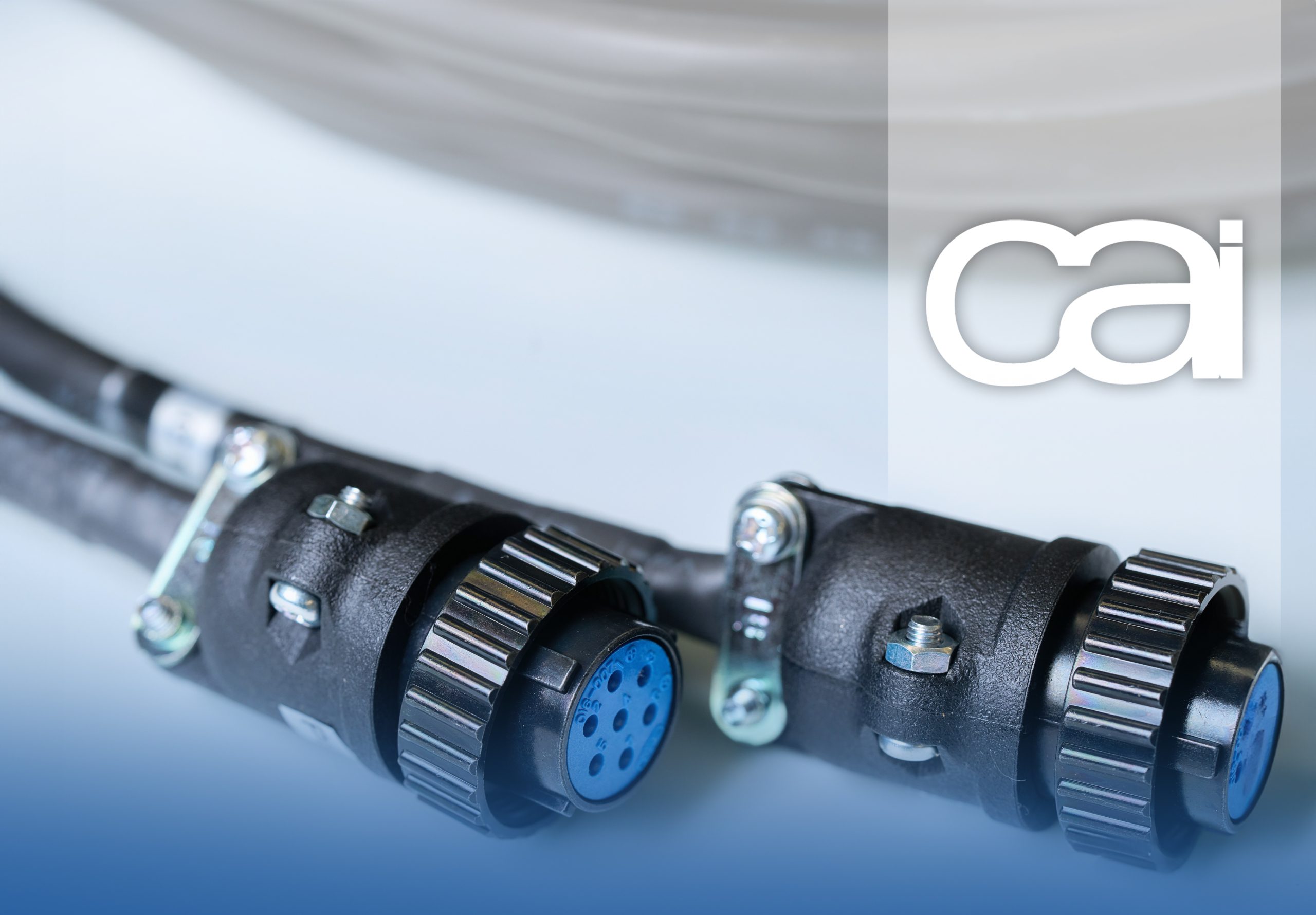

Since 1986, CAI has delivered custom-built, high-quality component and wire harness manufacturing to customers across the globe. Offering a personalized approach to every project, CAI partners with customers to create innovative products that exceed industry standards. Whether they’re creating niche product prototypes or helping a customer turn their idea into a full production run, CAI’s turnkey manufacturing approach delivers a complete product from design to delivery.

In-House Manufacturing Services

Industries We Serve

Military

Industrial

Automotive

Medical

Controls

Appliances

Robotics

Telecommunication

FEATURED SERVICES

Testimonials

The team at Corey Associates not only provides a quality product with quick turnaround on quotes and delivery but are great communicators and have excellent customer service. It is a pleasure working with the team over the past 5 years.

YOKOGAWA FLUID IMAGING TECHNOLOGIES, INC.

MAINE

CAI’s development support and production turnaround of the ruggedized over molded harness assembly, enabled the on time and successful launch of our recent supply system. Thank you all!!

PIMIOS

CRANBERRY TWP. PA

CAI quickly became a strong partner with their first-class service and the ability to deliver a quality product within a short amount of time. Their communication is outstanding, it should be the benchmark for any industry. It is a true pleasure working with the team at CAI.

VASTEX INTERNATIONAL

BETHLEHEM, PA

CAI’s domestic and offshore capabilities are a perfect blend for my client’s unique and dynamic custom cable requirements. They handle fast turn or blanket orders. They’re excellent communicators, provide great service, aggressive pricing, and aggressive lead times. They check all the boxes!

Owner, G2 INC.

I have worked closely with Corey Associates for the past 15 years. They have shown a perfect record in delivery and quality performance over that time. They are a helpful and cooperative supplier that we count on to meet our customer expectations.

Ken Smith

Director of Procurement

Legrand, North and Central America

CAI is a strong supply partner. They are customer and quality focused. Over the last 15 years, they have consistently provided competitive quality solutions to our requirements using both their domestic and international resources.

ENERCON TECHNOLOGIES

GRAY, MAINE